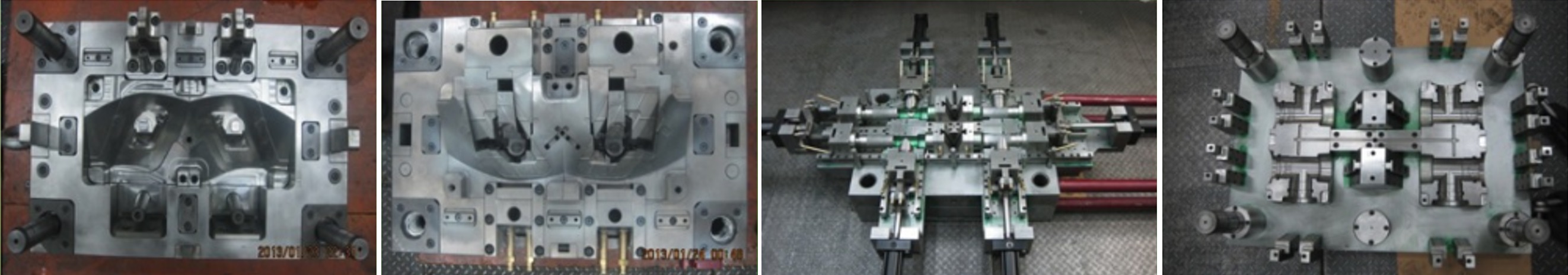

Our mould tooling helps create custom-made moulds that produce the parts in plastic injection moulding. We design and build precision moulds and transfer moulds for plastic components of the highest quality and have been doing since 1987. The steel material we use to build the moulds depends on the product requirement, production volume and budget indicated by our clients. Clients that required higher injection moulding production volumes are recommended to use hardened steel moulds. Our engineers have aided design in many projects which significantly reduced production and labor costs for our customers. You can be confident that we are able to manage the production of your product with ease under our one-stop service.

Here at Qiao Feng we have a team of professionals with over 30 years of experience to create bespoke plastic injection mould tooling for you. Qiao Feng acquires extensive experience in making two component (2K) moulds, gas-assisted moulds, rapid heat cycle moulds, mini moulds, and stack moulds to name a few.

Our equipment and facilities

Our factory covers 63,000square meters is fully equipped with a complete range of tooling manufacturing machineries with production capacity of up to 30tons. Our variety of machines enable us to provide you with a complete range of options for your product manufacture.

With the ever-changing technology within the moulding industry, we constantly invest in machineries to not only be up-to-date but also to become even more efficient with our manufacturing. To date, our factory is equipped with more than 160 sets of tooling manufacturing machineries. Our comprehensive mould manufacturing facilities are split into six different workshops and teams:

CNC,

Wire Cutting,

EDM,

Grinding,

Auxiliary and

Testing.

CNC

A CNC (Computer Numerical Control) machine is a high precision cutting tool that is computer-controlled. We use these machineries for cutting various hard materials, such as steel and aluminium. Due to the nature of the machinery, it is very customisable and is capable of doing mostly anything you require. Other benefits of CNC machineries are that it is robotics, consistent, produce high-quality work and improves factory productivity.

Within our CNC department is three centres: 5-axis Machinery Centre; High-Speed Machinery centre; and CNC Machinery Centre. We have over 20 machineries, mainly imported from Japan, Italy, and Taiwan.

Wire cutting

Our wire cutting machines, from Sodick and Seibu for example, have adaptive power control technology which automatically adjust the machining parameters promptly according to the shape and varying thickness of the part. As these machines are cable of performing at high speed with high accuracy, they largely improve our cost of production. This in turn benefits our clients to get their moulds with lower production cost.

EDM

The EDM (Electric Discharge Machine) process involves creating an electrical spark between an electrode and a workpiece. This electric spark produces intense heat with temperatures reaching up to 12,000 degrees Celsius. The spark usually takes place in the dielectric of deionized water and is very carefully controlled and localised, so that it only affects the surface of the material. The conductivity of the water is carefully controlled making an excellent environment for the EDM process. The water acts as a coolant and flushes away the eroded metal particles.

At our EDM centre we have almost 30 machineries, imported from USA, Singapore and Taiwan, that could cut small odd-shaped angles, detailed contours or cavities in hardened steel.

Grinding

Our grinding team is highly experienced in providing high surface quality and high accuracy of shape and dimension to the finish workpieces. We have over 20 in-house precision grinding machines to ensure we complete the grinding tasks well within project deadlines.

Auxiliary

We have a variety of auxiliary machines such as welding, die spotting press, drilling, milling, and supersonic polishing. The variety of our equipment makes it possible to build complicated and detailed designs. Within this department, we have imported over 70 machineries from countries including Japan, Korea, and Germany.

Testing

We can assure you of the quality as we are certificated with several ISO standards such as ISO 9001:2015. With almost 60 advanced high precision test equipment such as Three-Coordinate Measuring Machine, Optical Measuring Machine, Image Measuring Machine, Optical Comparator, Digital Display Height Gauge, Two-Dimension Measuring Instrument, and Rubbing Tester, we are confident in our production quality.